Developing software products is not a trivial task. Especially when talking about a complex app development process with a plethora of features, interrelated components, and massive inbound and outbound data flow. Logistics management systems are just of that kind.

To find out how to develop a logistics management system we’ll cover a few important aspects. They include basic structural components of a logistics management system, common technical solutions for each module of logistics management software, and a few examples of third-party providers that can help with some issues related to data management.

Having covered these points, we’ll get a universal roadmap on every key stage of logistics software development. Brace yourself and buckle up — there’s a lot to discuss. But we’ll do our best not to leave any of the definitive points out of the story.

Why do businesses invest in logistics management software?

The level of circulation of goods and services has always been a factor in prosperity and economic growth. The volumes are getting bigger, the routes more diverse, and the markets more expansive and competitive. The logistics industry wins wars, strengthens domestic and international connections, and creates millions of jobs worldwide.

With that said, governments and enterprises are generously investing a fair share of financial and material resources in logistics software, expecting more profits from such a vital niche. For instance, logistics startups are accumulating billions of dollars from for-profit companies. And Businessinsider is actually observing a historic funding boom in the logistics industry. On top of that, authoritative portals on logistics insights agree that practically all transportation and logistics niches like rail, shipping, and even postal services are thriving and constantly moving towards developing innovative logistics management software features.

Considerations before you start

Not all business needs require developing a gigantic logistics software infrastructure. There are plenty of ready-made software solutions with cloud-based storage, automated backups, and adjustable features.

Nevertheless, provided you want to have control over the logistics app development process and the supporting documentation, the first and most important step is careful planning and estimation of such a considerable effort.

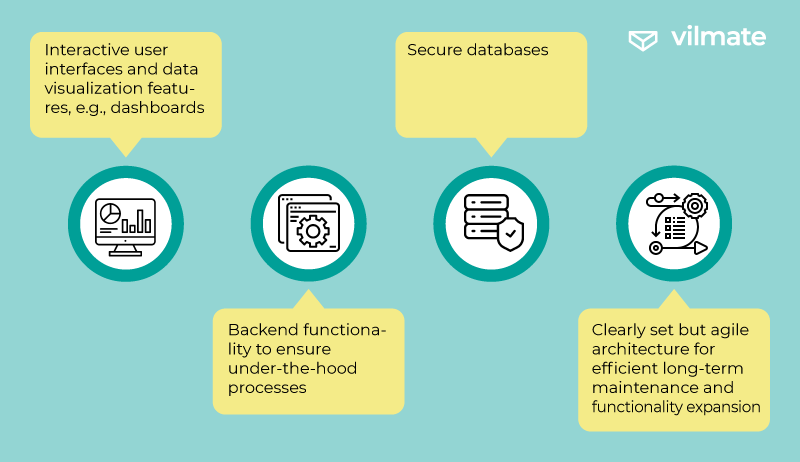

The biggest difficulty of an operating logistics management system is that it consists of software modules that perceive different goals. We’ll cover the modular structure of an LMS in the next section, but, in any case, all of them need to have some fundamental operational assets.

So keep in mind that you’ll have to establish teams with frontend and backend developers, not to mention QA specialists and UI designers.

But what units will you have to operate with while creating a logistics management system? It’s time to make a quick overview of basic logistics software modules and see how they complement each other in order to increase logistics system efficiency.

Logistics management system structure overview

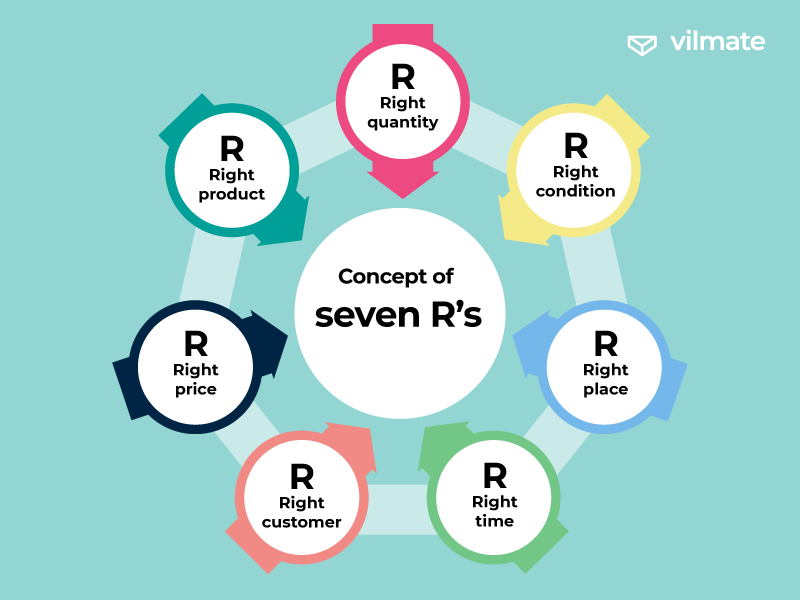

The most common concept of logistics and transportation management is the concept of seven R’s:

- Right product

- Right quantity

- Right condition

- Right place

- Right time

- Right customer

- Right price

For all these R’s to work in tandem, the management system operates in close touch with logistics software modules:

- Order management

- Inventory management system

- Warehousing

- Transportation management system

- Analytics

We won’t be stopping on any of them in too much detail. Let’s just look through the tasks that each of them is designed to deal with.

Order management module is usually integrated with other software like accounting and billing as it’s responsible for customers’ order fulfillment. Modern order processing systems act as a centralized platform for order placement, picking inventory, sorting, tracking, and even consolidation with other orders for cost-effective shipping.

Inventory management is about storing, tracking, ordering, and selling a company’s inventory. It can be raw materials, finished goods, or merchandise (goods a company buys from a supplier for future resale). The main purpose of the inventory management system is to avoid shortages or excesses of the available products.

Warehouse management module combines software solutions to provide visibility of warehouse filling, manage distribution among stock, and maintain the overall conditions of storing goods.

Transportation management solutions deal with the physical movement of incoming and outgoing goods. Freight management, route planning and optimization, fuel consumption, and safety measures are the main focus of this module of a logistics management system.

Logistics analytics is used for analytical procedures aimed at analyzing and coordinating the logistical function and supply chain. Analytics ensures the smooth, timely, and cost-effective running of all the logistics operations.

Let’s now see which software solutions one has to focus on, having decided to develop a logistics management system from scratch.

What you need to develop logistics management software

As mentioned before, logistics management software features differ in their purposes, therefore, in their architecture and development approaches. So don’t expect that one team can simultaneously work on all of them, giving their best performance.

Instead, focus on the specifics of each module separately in order to apply the most relevant technical solutions.

Order management & processing

Let’s start with order management software. This module is of major importance as it’s used by both customers and logistics providers. Practically all e-commerce platforms contain order processing features and are expected to have user-friendly interfaces as well as swift backend functionality for order fulfillment. Moreover, a well-established order management system provides visibility over the whole process of order fulfillment – from pressing the ‘buy’ button by a customer to the actual delivery to the door.

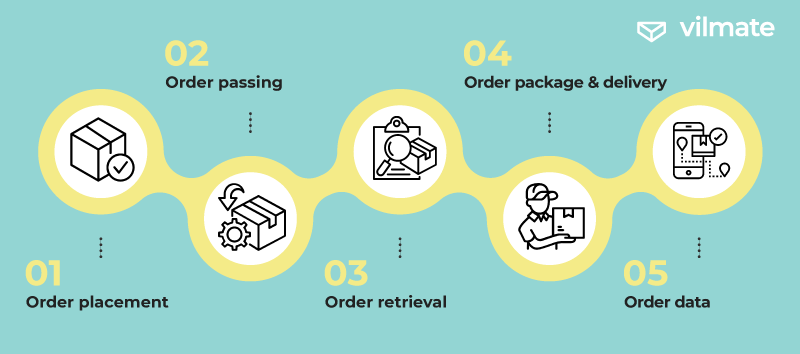

In general, the order management cycle consists of 5 main steps that require careful attention in the process of development.

1. Orders are placed by customers across available channels.

Designing a graphical user interface with the use of HTML, CSS, and JavaScript is the first big step. The look and feel of a portal (web or mobile) play a key role during the client-side software development process. Buttons, links, animations, and other interactive frontend components should be stylistically appropriate and give an intuitive understanding of what they’re representing.

2. Orders are passed to the order fulfillment center for further processing.

This is where orders receive their unique tracking IDs, and the information about the product’s quantity, specifications, etc., is passed to one or multiple fulfillment centers. The client-server connection and the communication lines with inventory databases should be the main focus of the software development team. Cloud-based solutions and digital pipelines for data flow are common for this stage of order management system development.

3. The products for each order are picked from inventory lists and retrieved from storage.

Another stage where inventory and warehousing modules operate in close connection with order management systems. The better inventory lists and stock operations are arranged, the less time it’ll take for order processing software to get to the next step. And again, efficient backend development for safe and quick travel of the customer and order information is the primary issue to solve.

4. The ordered products are packed, consolidated, and delivered to the customer.

Orders are usually packed and consolidated in warehouse distribution centers. And the delivery is maintained by the transportation management software. Nevertheless, the ongoing status of an order must be tracked and highlighted by order management software. Real-time status checks with updates of information for customers are a must-have for any order management system.

5. All the data produced by the process of order fulfillment is stored and analyzed for further logistics coordination improvement.

Vast amounts of data about each stage of logistics operations must be securely stored but easily accessible at the same time. Ensure optimal cloud or on-premise data storage solutions. The options of giving feedback from customers (no matter positive or negative) on the conditions, time, payment procedures, and convenience of product ordering and delivery must be integrated into order processing systems.

So let’s sum up the features that can’t be omitted while developing an order management system:

- Interactive user interface with feedback options

- Integrated payment transaction features

- Stable client-server connection

- Backend functionality to exchange data with other modules

- Regularly updated status information display

- Secure and easily-accessible databases

- Analytical tools for improving efficiency and reducing costs

Inventory & warehouse management systems

These two modules can be discussed in a bundle as they’re closely connected and can often apply to similar technical solutions.

Warehousing, as well as inventory management systems, are an essential part of any company that needs to keep track of their goods and materials. Without inventory and warehouse management software, companies would not be able to know how much product they have on hand and how much more they need to order.

There are many tools that can be used to create inventory and warehouse management systems. The type of tool depends on the needs of the company. For example, a small company might not need a cloud-based application, while larger companies might need one to manage their operations more efficiently.

In the process of software development related to inventory and warehousing, the key thing to consider is that there are 3 main components: lists, software, and hardware.

- Lists help with data entry.

- Software helps with data processing.

- Hardware helps with storing information on physical objects like pallets or containers.

The software can provide templates for different types of lists. While lists are the backbone of these management systems. There are many different types of lists that can be created for inventory and warehouse management. Some examples include:

- Items on hand

- Items that need to be ordered

- Items that need to be restocked

- Items in storage

- Items in transit

Modern practices of working with listed data include visualization for better comprehension. Python libraries like Matplotlib, paygal or Folium are often appreciated by developers for their simplicity and effectiveness.

Transportation management system

There are various factors that one should consider when developing a transportation management system. Any operating supply chain management system relies on efficient transportation management solutions to a huge extent.

- The first factor is the type of transportation: air, ground, rails, or maritime.

- The second factor is the number of vehicles used in the transport process.

- The third factor would be the type of service: door-to-door, point-to-point, or mixed service.

- The fourth factor would be the congestion or load factor: the number of vehicles attempting to use a specific transportation mode at a given point in time.

- The fifth factor is the seasonality of the transportation mode.

Transportation management in logistics should help manage the resources in route planning and ensure that they’re used in an efficient manner. So among technical solutions for implementation in transportation management software, we can point out GPS tracking systems, cloud and SaaS solutions, and Uber-like applications for drivers and freight management operations.

The top 3 examples of ready-made solutions that embrace major benefits of transportation management systems for companies of any scale are as follows:

Logistics analytical module

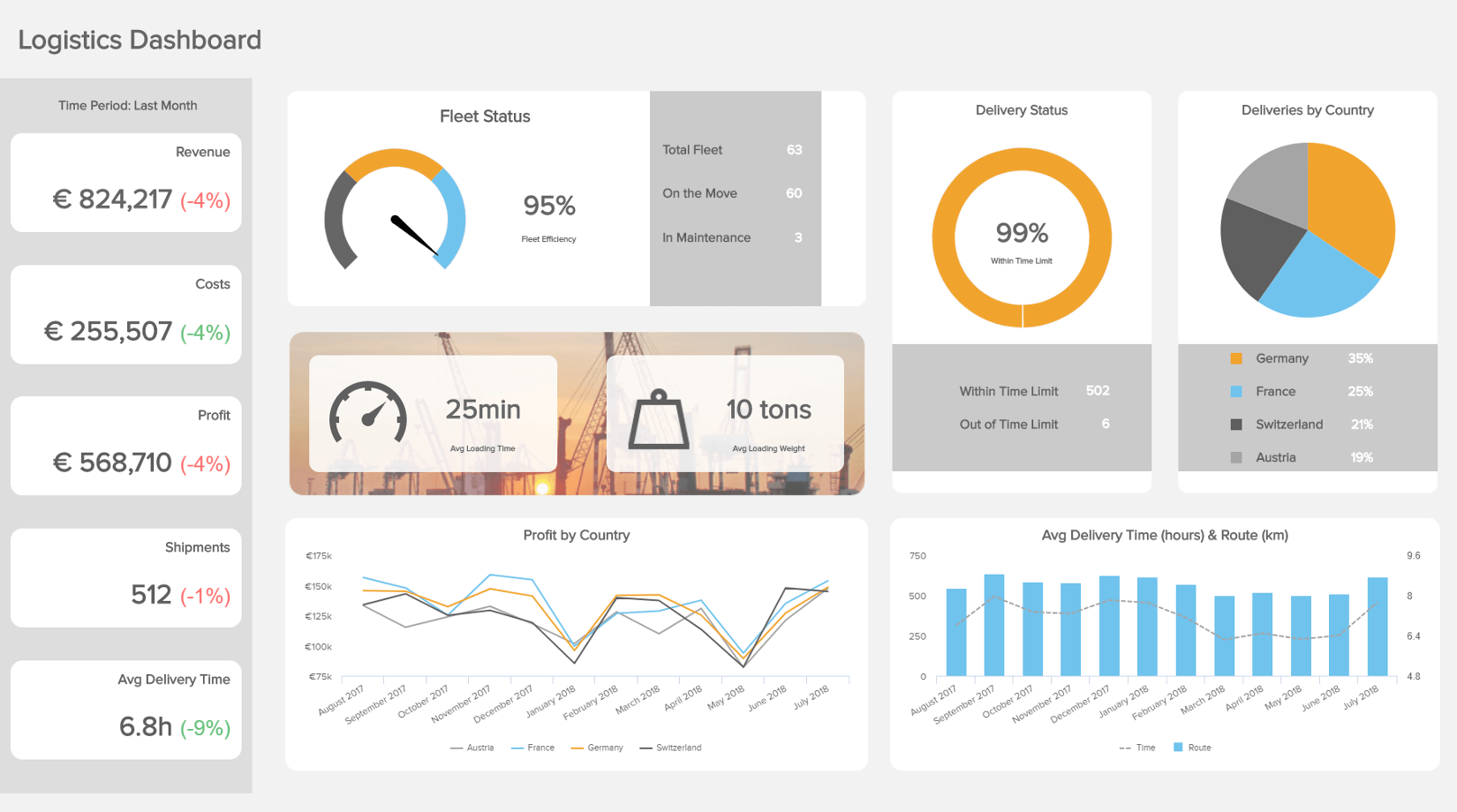

Logistics analytics consists of control screens and graphs with information collected on logistics operations. This information is centralized and visualized for making more balanced business decisions, logistics planning, and avoiding risks. Customer information, product transfers, returns, weights, limits, and other details produce large-scale data flow, which serves for optimal data-driven business models.

Similar to warehousing and inventory management development techniques, the use of data visualization libraries is quite common. On top of that, professional logistics dashboard templates provided by third-party companies can surely ease the task of real-time monitoring, categorizing, and centralizing the relevant data.

Examples of such providers include Deloitte, Tableau, SAP Ariba, and Qlik.

At the same time, developing and setting up a logistics management application is only the beginning. Logistics management system maintenance is no less important and oftentimes requires even more effort for operational sustainability.

Logistics management software maintenance

If you want your company’s logistics management system to function at its best, then it is important that you do the necessary maintenance work on it regularly. This will help avoid any problems with the performance of your company’s supply chain management. It also ensures that the software is compatible with the latest updates in technology regardless of the type of logistics software.

Here is the list of general procedures that should be applied for effective integrated logistics management:

1. Periodically inspect your logistics management platform.

This is usually done by auditing and reviewing the current logs, reports, and documentation of the logistics management system. The reviews are done whenever there is a need to identify performance, ascertain capacity constraints, or review findings from previous audits of all the logistics management software features.

2. Collect information about transportation and logistics systems and their environment before audits.

The goal of this activity is to create an understanding of the state of logistics software and its environment so that issues can be recognized and remediated more effectively when they occur.

3. Set up a backup for all the data in case of any data loss or corruption.

There are many ways to make a backup of your data. You can either use a cloud service provider or set up your own backup server. The most popular way to backup data nowadays is by using the cloud service providers such as Google Drive, iCloud, OneDrive, etc. You can upload all your files and documents and keep them safe from corruption or data loss in case something happens.

Final words

So this was a general roadmap on how to develop a logistics management system. In order to get the desired result, first, you should identify the goals and objectives of your company. Then you need to create a strategy for reaching those goals and objectives. Finally, create an implementation plan that will help you reach your goals and objectives in an effective way.

Don’t forget to check our Portfolio and Technologies to get an idea of which components we can take care of in your existing or potential projects. We always provide high-quality Services and a transparent reporting system. Also, our specialists are seasoned in an agile approach and precise estimations and are open for discussion anytime.

And to finish, here’s what Sun Tzu, a Chinese strategist and philosopher, said regarding the topic: ‘The line between disorder and order lies in logistics.’

Stay tuned with Vilmate! And contact us whenever you’re ready :)